Prestige Industrial Roofing Supplies are one of the UK’s Leading Industrial Metal Cladding Suppliers.

As one of the major industrial metal cladding suppliers, we offer a comprehensive and competitively priced range of products, including aluminium cladding panels, steel cladding, zinc cladding, composite cladding and curved metal cladding.

Our Industrial Metal Cladding Products

At Prestige, we know the hassle involved in phoning around different suppliers to get what you need first-hand. We have an impressive portfolio of steel cladding, zinc cladding, aluminium and composite cladding products from proven manufacturers. As a result, whatever your requirement, rest assured that Prestige has you covered for all industrial metal cladding requirements.

Well Connected for Metal Panel Supply

We only work with and supply high-quality products from trusted manufacturers. This means you can that you can have total confidence in the products we supply, many of which come with extensive manufacturer warranties. We offer our customers the advantage of being able to obtain all the supplies they need, when they need them.

Close links with major manufacturers mean that we can provide quality products at competitive rates. Trust is at the heart of what we do. We supply the best industrial solutions from Tata, Joris-ide, and many more. This saves you going anywhere else for your supplies.

We can quickly supply you with a wide range of industrial metal cladding panels that can be laid vertically, horizontally or even diagonally, depending on your building’s needs. We even fabricate shaped cladding for the most unusual of requests.

In fact, we’ve made the purchasing process simple. Since we have many years’ experience in the trade, we co-ordinate your deliveries to help keep your project on track. Our national logistics network delivers the steel metal cladding, zinc cladding, copper, and aluminium cladding panels you need quickly, easily and cost-effectively.

Metal Cladding FAQs

What is metal cladding?

In industrial building terms, metal cladding is used on the outer surface of a building to protect it against corrosion and abrasion.

In simple terms, metal cladding is a protective layer to a building. It shields the internal building structure from the elements and can improve the stability of a building.

As metal cladding suppliers, we typically source four types of metal cladding (steel cladding, aluminium cladding panels, zinc cladding and copper cladding).

Metal cladding can be applied to roofs and walls, on both horizontal and vertical surfaces, and can even be applied to curved facades and bespoke shapes.

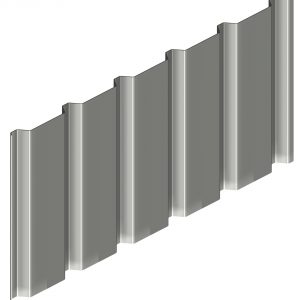

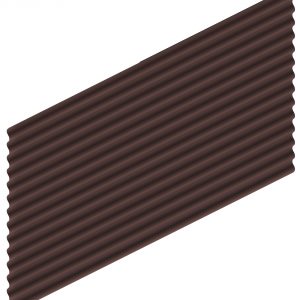

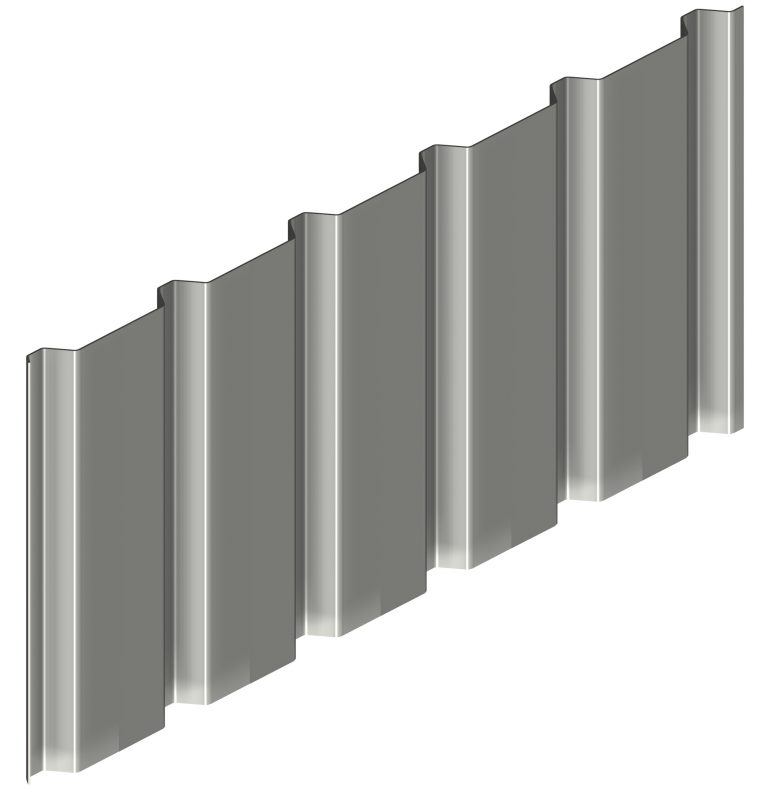

From a technical point of view, metal cladding is available in a wide variety of profiles (including corrugated), or it can be laid flat as part of a panel-based system. To find out more about the products we supply, please browse our website or if you cannot find what you are looking for, give us a call.

What is the best type of metal cladding to use?

Metal cladding can be found in a wide variety of projects, from industrial warehouses and agricultural buildings to high-end commercial outfits. So how do you choose the best metal cladding panels or cladding for your project?

Without meaning to be too simplistic, the following guide we find is quite useful.

Steel cladding

Steel cladding is a durable and cost-effective form of metal cladding. Usually coasted with a polymer product (usually polyester or plastisol) to prevent rust and corrosion, it is available in a range of colours and designs, making it ideal for commercial, agricultural and industrial applications. Steel cladding sheets can also create structural integrity and prevent warping, making it a popular choice for warehouse constructions.

Aluminium cladding panels

Aluminium cladding panels may be lightweight, but they are incredibly strong, and so installation tends to be easier. That’s why it’s often the preferred metal cladding product to use in refurbishment projects. It’s also perfect for over-cladding an existing substrate on an industrial build.

Zinc cladding

Where rusting may be a consideration, zinc cladding is often a good option. In fact, some architects and specifiers choose zinc cladding for the ‘patina’ colouring that forms when zinc is exposed to the elements. Moreover, light abrasions effectively disappear as the metal weathers, making it a popular choice for commercial outlets and offices.

Copper metal cladding

Copper is the most expensive type of metal cladding. Renowned for its colour change over time, it is usually specified in buildings designed to make a visual impact. It’s not unusual to find copper cladding on university buildings, museums, and other iconic buildings.

What are the different metal cladding profiles?

There are lots of different metal cladding profile sheets commonly used in industrial, agricultural, commercial and leisure building.

In response to roofing contractor demand, there are a range of corrugated and other profiles, including trapezoidal, sinusoidal and half-round. Leading metal cladding manufacturers coat metal cladding profiles with protective preservatives and liquid plastic coating to provide a wide range of textures and colours.

There are four types of metal cladding profile materials that are used, and these are steel cladding, aluminium cladding panels, zinc cladding and copper cladding.

In industrial roofing, there are different types of metal cladding sheeting systems, including built-up sheeting, composite, snaplock, and standing seam.

Built-up sheeting involves sheeting being assembled on site and consists of four elements (an internal line, insulation, spacer bars to support the metal cladding, and profile metal cladding panels).

Composite systems involve two metals being bonded to an insulating core. The composite material is simply sandwiched between steel cladding, aluminium cladding panels or zinc.

Like composite systems, snaplock includes insulation and liners but rather than being bonded together they snap-lock into place for a quick installation.

Standing seam systems are either distributed by metal cladding suppliers as pre-insulated metal cladding panels or as metal sheets that are formed and ready to be applied to substrate on site.

Cassette systems, which are perfect for industrial sized cladding areas, are open-jointed and can be used in metal cladding panels up to 13ft in length. The cassettes are simply fixed with invisible clips to an aluminium frame to create a sleek modern finish.

What fixings do I need to specify for metal cladding?

There is a wide range of fixings to choose from for the installation of steel cladding, aluminium cladding panels, zinc cladding and copper cladding products.

As you would expect, different metal cladding products require different fixings; something that’s also crucial for maintaining the warranty of metal cladding.

There are several different types of metal cladding fixings, and these are:

- Light metal fixings – used to fit galvanised z-purlins

- Heavy steel fixings – for use on heavy gauge purlins and those with a box channel

- Stitch fixings – for sheet to sheet fixings and fastening flashings to steel sheets

- Double six fibre cement fixings – for use on wooden batons or light metal purlins

- Hook bolts – for right angle metal beams

- Blue concrete fixings – for fixing metal cladding and flashings to concrete

As one of the UK’s leading metal cladding suppliers, we constantly see new fixings come to market. If you are unsure of the exact fixings you need, we’ll be able to tell you.

What is metal cladding coated with?

As part of the manufacturing process, metal cladding is coated with a composite or powdered material for maximum protection against corrosion.

Using TATA steel cladding as an example, the most popular finishes include plastisol, HPS, Colorcoat prisma and polyester.

Plastisol is often applied to steel cladding. It is a suspension of PVC (Poly Vinyl Chloride) in liquid plasticizer which is rolled on to the metal. Frequently used to clad roofs and walls of industrial buildings, it offers excellence corrosion resistance.

Colorcoat Prisma and HPS are metallic coatings offered by TATA steel and are made with a special mix of 95% zinc and 5% aluminium. Available in a range of colours and offering colour stability for 20 years, both are a great choice for contemporary architects.

Polyester coated metal cladding is also a good option, especially for commercial buildings and warehouses. The steel cladding is simply dipped in a galvanised coating of 275g per square metre and is primed and coated with 25 microns of high quality Polyester enamel paint.