Prestige Industrial Roofing Supplies are one of the UK’s Leading Suppliers of Metal Wall Sheets.

From corrugated metal wall panels, aluminium metal wall sheets, to galvanised steel sheets for walls, Prestige has you covered. As a leading supplier of metal wall sheets, we offer one of the largest and most competitively priced ranges of metal wall sheeting.

Our Metal Wall Sheets

We have an impressive range of metal wall sheets for you to choose from, covering all metal wall sheeting types from proven manufacturers. Prestige understands first-hand that complex jobs require many different solutions. Why add to the pile with phoning around multiple suppliers? We’re your one-stop-shop!

PIRS only works with and supplies high-quality industrial and commercial metal wall sheets from trusted manufacturers. As a result, you can have total confidence our sheet metal wall panels, many coming with extensive manufacturer warranties.

As such, we supply the best industrial metal wall sheets solutions from Tata, Joris-ide, and many more. This saves you going anywhere else for your metal wall sheets.

We can quickly supply you with a wide range of metal wall sheeting including box profile metal wall cladding panels and sheets, corrugated steel sheets for walls, decorative aluminium sheets for wall and bespoke specifications.

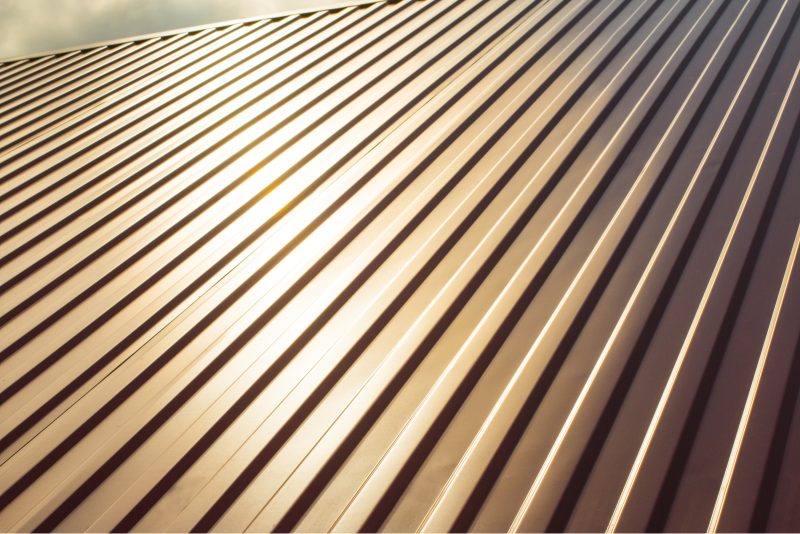

Many of our commercial building metal wall sheeting products are polyester paint coated or plastisol coated for visual appeal. Therefore, we’re able to advise on a wide range of finishes. We pride ourselves on our knowledge of metal coatings, and eye for finishes!

Metal Wall Cladding Panels Done Right

Best of all, we’ve made the purchasing process easy. With many years’ experience in the trade, we co-ordinate your deliveries to help keep your project on track. Our national logistics network delivers the metal wall sheets you need quickly, easily and cost-effectively.

Projects and jobs should be done on time and on budget, and we wouldn’t have it any other way. Get your corrugated metal wall panels and metal wall sheets from the professionals.

Metal Wall Sheets FAQs

What are metal wall sheets?

In industrial roofing terms, sheet metal wall panels are made from a rigid layer of insulation that is sandwiched between to metal skins. The resulting metal wall sheets are strong, lightweight and durable.

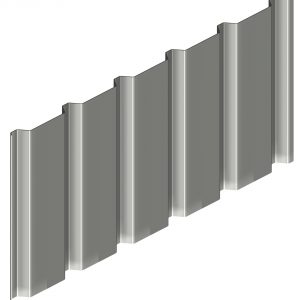

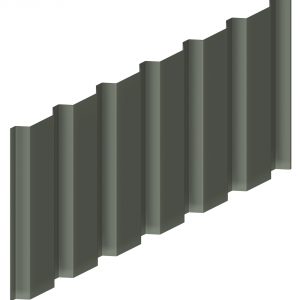

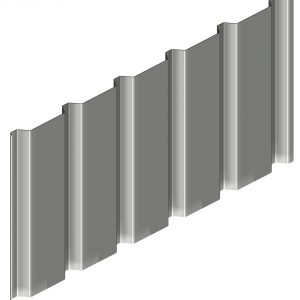

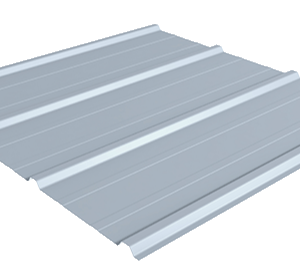

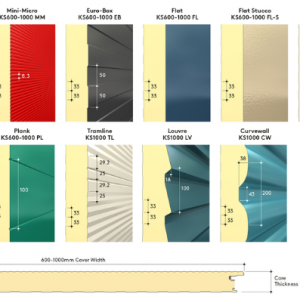

There are different types of metal wall cladding sheets. Popular with industrial and commercial builds is composite metal wall cladding. Available as either a standing seam or a fixed system, and in either a trapezoidal, shallow profile or micro ribbed sheets, profiled composite metal wall sheets are designed to allow rainwater to run off. Being available in different colours, they are also chosen for their aesthetic appearance. In a profiled composite panel, PIR is the most common type of insultation sprayed onto the metal wall sheeting to provide enhanced thermal and acoustic insulation.

As a leading metal wall sheets supplier, PIRS provides the full range of Kingspan composite panels, architectural steel sheets for walls, box profile insulated wall panels and more.

We also offer the full range of Joriside metal wall sheets, including trapezoidal wall panels, slate effect, eco panels and more.

Similarly, we have an excellent supplier relationship with TATA steel that also manufacture a large variety of sheet metal wall panels.

Where are corrugated metal wall panels used for?

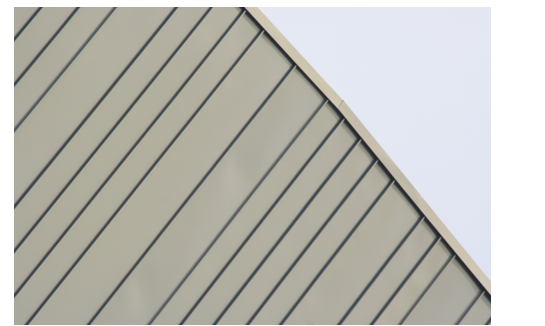

There’s no exact rule. However, corrugated metal wall panels tend to be used a fair bit in conservation areas and in agricultural buildings.

Incredibly durable, corrugated metal wall panels withstand even the harshest of weathers and usage. Most importantly, corrugated wall panels add to the structural integrity of a building. When compared to other materials they are often far superior. As any roofing contractor will already know, the corrugated patterns are designed to maximise the flexibility of the metal wall sheets.

Corrugated wall panels can endure high usage and can withstand larger loads, meaning that once constructed they last for many years.

Crucially, the design of corrugated metal wall panels allows for the easy passage of rainwater. The vertical corrugated wall panels effectively direct water, snow and general debris away from the roof, helping the building to remain rust free.

What sizes do metal wall sheets come in?

The maximum size of metal wall sheets depends on the type of product specified. Corrugated metal wall panels are available in a wide range of sizes. However, the standard widths tend to be 26 and 36 inches and are usually available in two thicknesses (0.5mm and 0.7mm).

Similarly, composite metal walls sheets are offered in a wide range of sizes and profiles. Kingspan’s composite steel and aluminium panels, for example, cover a width of either 1000mm or 2000mm and come in thicknesses from 71mm to 181mm.

Being an approved composite metal walls sheets supplier with several manufacturers, including Kingspan, we can source all manner of metal wall sheets at a competitive price.

When you speak to us about corrugated wall panels or metal wall sheets, you’ll find that we have a wealth of knowledge you can tap straight into. Our clients find this particularly helpful during the specification process.

How are metal wall panels installed?

Since metal wall sheets are effectively a water, air, vapour and thermal barrier, it’s important that they are fitted in accordance with the manufacturer’s instructions.

Most metal wall panels are quick and easy to install. However, there are a few things that need to be carefully considered ahead of installation.

The structural frame of the building should be properly designed to accept the metal wall sheets, and the interior/exterior panel joint and perimeter seals must be correctly specified.

Many metal wall sheets can be supplied prefabricated. Others will need to be cut on site using a specialist metal cutting blade. To prevent surface rust, all metal shavings must be removed, and any exposed sealants must be cleaned.

Before sheet metal wall panels are lifted into place, the sealant must already be applied in the panel joints. If the panels come with factory-applied sealant, it’s good practice to inspect the panels first to make sure there is an even sealant application.

Next, the metal wall cladding panels (or sheets) are lifted into place, often with suction equipment. However, you may be working on a smaller build or in a restricted area. If this is the case, be careful not to lift too many metal wall sheets at once as this may cause over-flexing.

You will also want to make sure you are using the correct fixings, which we are all too happy to advise on. Generally speaking, concealed clips and tek fasteners are preferred. In all cases, you should use the fasteners and clips recommended by the metal wall sheets manufacturer.

Who are the main metal wall sheet manufacturers?

There are several metal wall sheets manufacturers that are either based in the UK or supply directly to the UK.

At PIRS, we only work with high-quality metal wall sheets manufacturers that we can trust to quickly provide products that will do just the job. In our opinion, the leading manufacturers of metal wall cladding panels and metal wall cladding sheets include (in alphabetical order):

- Euro-Bond

- Joris-ide

- Kingspan

- Tata Steel

Working closely with the manufacturers means that PIRS can confidently and quickly supply any quantity of corrugated wall panels or sheet metal wall panels in the UK. We also aim to be more than just a supplier – our customers come to us for our many years’ experience in the sector and trust the product recommendations that we make since we are not tied to a metal wall sheets manufacturer. Our focus will always be on sourcing exactly what you need at a competitive cost.