Prestige Industrial Roofing Supplies, UK’s leading Roofing Fixings Supplier.

We deliver a full range of tech roofing screws, roof fixings and fasteners, corrugated roof fixings, cladding screw supplies and roofing screws.

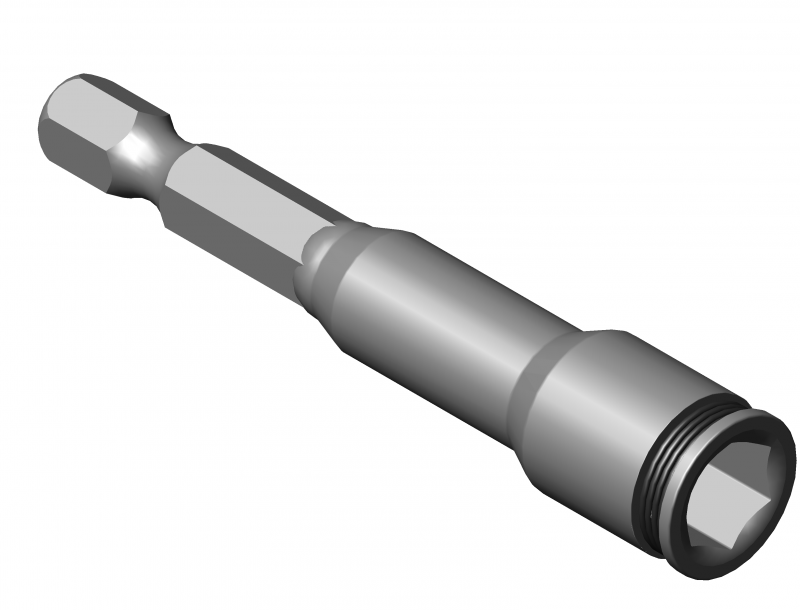

In addition, we also source Decktite pipe flashings, corrugated fibre cement fixings (baz fixings), heavy & light steel metal tech screws (carbon & stainless steel), rooflight fixings, drill sockets, stitching fasteners and timber roofing fixings.

When you purchase roof and cladding fixings through us, we’re ready to supply everything you need to complete the job.

We stock various fixings and fasteners, including cladding screw and nail fastening systems. Not only this, we’ll help you choose the correct fixings for your job. Whether that’s moulded head composite panel roof fixings, robust concrete roofing screws, heavy or light steel technical fixings, rooflight fixings, carbon steel stitchers or timber tech fixings. We’ve got it covered.

We partner with manufacturers whose roofing and cladding fixings offer practical high-performance solutions for all applications. This means you can be confident in the roofing fixings products we supply, many coming with extensive manufacturer warranties.

Your One-Stop Shop for Roofing Fixings

Our customers benefit being able to obtain all the industrial roofing fixings and equipment required from one place. Close links with major manufacturers mean that we can provide quality products at competitive rates. Every day we introduce new roofing screws, roof fixings and fasteners, such as Ash & Lacy and many more. This ensures you can purchase all your roofing fixings supplies from us.

Our in-house technical knowledge is second-to-none. Consequently, if you’ve specified a new product and need some advice on the best cladding and roofing screws or nail fastening systems, we’re the people to talk to. We’re not just a regular roofing fixings supplier. We have many years’ experience specifying roofing, cladding and insulation products. It’s something our clients lean on us for. So, if you need some help deciding on the best roof fixings and fasteners, give us a call on 01268 858444.

Best of all, we’ve made the purchasing process simple. Since we have many years’ experience in the trade, we co-ordinate your deliveries to help keep your industrial roofing project on track. Our national logistics network delivers the industrial roofing fixings products you require quickly, easily and cost-effectively.

Roofing Fixings FAQs

What are tek screws?

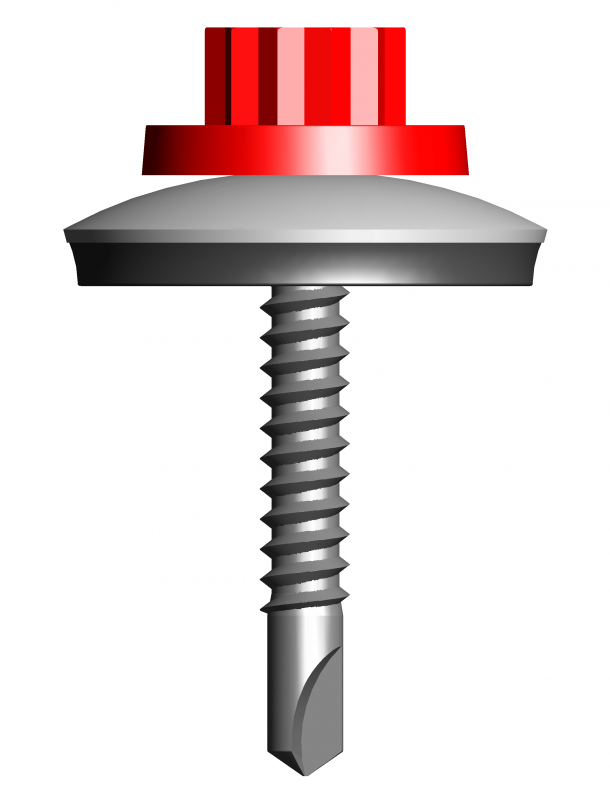

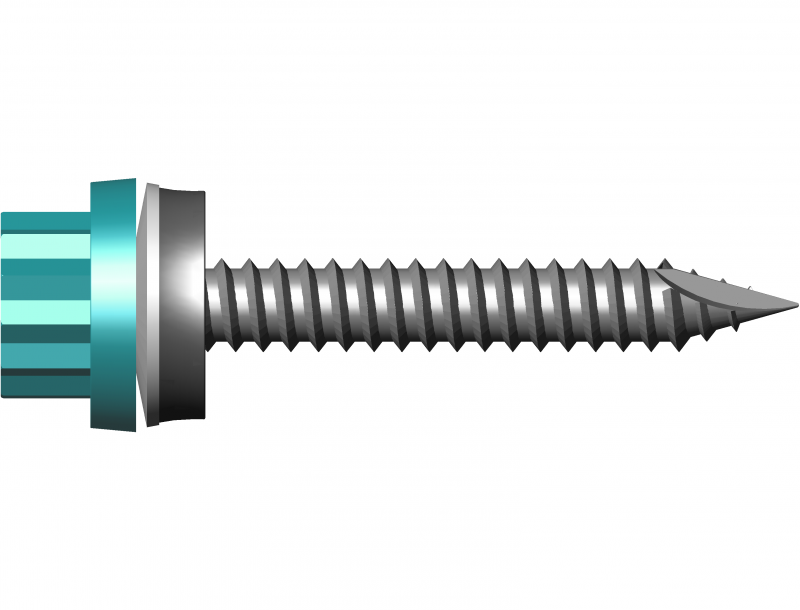

Tek screws, also referred to as tech screws, are self-drilling roofing screws that make it far easier to complete roofing installations. These clever tech screws do not need a pilot hole. Therefore, they’re quite nifty at securing roof fixings since they pre drill and fasten in a single motion.

For heavier works, we do stock tek roofing screws suitable for use with a drill or by hand. All our roof and cladding screw products are available in a wide range of lengths, widths and finishes.

What are tek screws used for?

As specialist tech screws, tek screws are used within a wide range of roofing work including sheet to steel, sheet to sheet and timber to steel. Why they are so good for these types of applications is that they are self-drilling, meaning they do not need a pilot hole. Pre drilled, tech screws fasten (either by hand or drill) in a single motion.

As roofing fixings, they’re perfect for securing steel sheet to sheet purlins.

As the use of tech screws is quite wide, their design varies considerably. They are manufactured in a huge variety of shapes and sizes, usually with hexagonal or torx heads, although some have inbuilt washers. They are specifically coated for corrosion.

How far apart should metal roofing screws be?

As a general rule, metal roofing screws should be placed about one and half to two feet apart, although no more than this. It really depends on what the metal roofing screws are securing in place and the structure of the roof.

It’s important that they are not placed too close together either. For example, corrugated roof panels are normally secured in place with roofing screws every 2ft.

While the width apart is important, so too is the placement of roofing screws on metal roof panels. Metal roofing screws should be installed down inside the flat of the panel and not on top of the rib. If positioned on top of the rib, there’s an increased chance of them tilting and widening the hole to make the panel come loose.

How do you install metal fixings and fasteners?

Correct metal roofing installation starts and ends with the use of the correct fixings and fasteners. Therefore, there are a few things that need to be taken into consideration.

Firstly, it is important to use the correct metal roofing screws since they will not bend like nails or work themselves loose when the roof contracts. Most importantly, you must ensure that metal fixings and fasteners (roofing screws) are placed correctly for a tight fit. Steel roofing screws should be inside the flat of a roofing panel and not the top of the rib otherwise they may tilt, stretch the hole and come loose.

What is a cladding screw?

The cladding screw is quite a novel technology in terms of fixings and fasteners. Most have a raised countersunk head with milled ribs just beneath to ensure they easily sink into cladding. The carefully cut points on the cladding screw make for precise placement without pre-drilling, although this is wood-dependent. Each cladding screw is resistant to corrosion and rust. These types of cladding fixings are available in a wide range of colours and finishes to complement the surrounding cladding.