The UK’s Leading Roof Purlins, Eaves Beam, Z Purlins & C Section Purlin Supplier.

As a leading roof purlins and steel purlins supplier, we offer a comprehensive and competitively priced range of product options including roof purlin supplies, eaves beam, roof and side rail Z purlins & C purlins for sale.

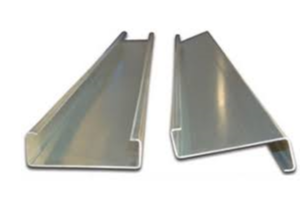

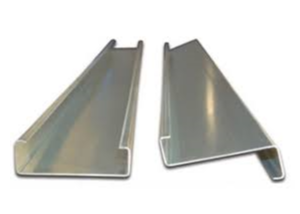

When it comes to Roof Purlins, we understand that lightness and strength are essential. These are needed for constructing cost-effective roofs, facades, partition walls and floors. Because of this, we supply a huge range of quality C and Z purlins and Eaves Beam sections.

Specialising in roof purlin supplies, we partner with manufacturers whose roof purlins offer practical high-performance solutions for industrial and commercial applications. You can have total confidence in the products we supply as a result, many coming with extensive manufacturer warranties. We offer our customers the advantage of being able to obtain their supplies from a one-stop shop. Get all the roof purlins, eaves beam, Z purlins and C section purlins products, tools and equipment required from a single, reputable source. Close links with major manufacturers mean that we can provide quality products at competitive rates.

The manufacturers we partner with are well-known for their high-quality and profile accuracy. Supplied either un-drilled or drilled, our Z section and C purlins for sale can be manufactured at up to 8m lengths in a range of thicknesses, whether flat or angled.

Access Extensive Roof Purlin Supplies

So, whether you need a C section purlin to form the walls and floor joists of a building shell, Z purlins or an eaves beam for top sheeting rail and gutter support, we’ve got it covered.

As a purlin supplier, our in-house technical knowledge in the field is unmatched. We’re delighted to say it’s something our clients lean on us for when choosing steel roof purlins. If you’re unsure on the exact specification or simply want to explore or want to add more options to your order, we can help.

Best of all, we’ve made the purchasing process simple. Since we have many years’ experience in the trade, we co-ordinate your delivery to help keep your project on track. Our national logistics network provides a dependable service, delivering the Roof Purlins, eaves beam, Z purlins & C section purlins you require quickly, easily and cost-effectively.

Roof Purlins FAQs

What different types of roof purlins are there?

Roof purlins support the load of a roof deck (the wood panel, ply, or metal sheeting surface of a roof). There are several different types of roof purlins, including wood and steel purlins.

However, as a leading industrial roof purlin supplier, we know that most builders tend to use steel purlins. Essentially, steel purlins are a direct replacement for wood. They are chosen for their structural strength, are lightweight and expand and contract to an acceptable tolerance even in extreme weather.

Steel purlins are manufactured from cold-formed steel that can be held in place by screws. These type of roof purlins are made by pressing thin sheets of steel into specified profiles.

To provide a good level of protection, galvanised steep purlins are also coated with a protective layer to protect against corrosion.

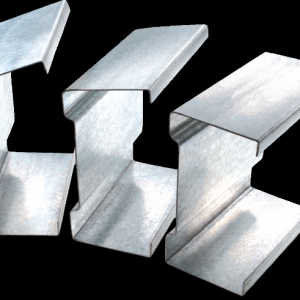

With steel purlins there are two main profiles to choose from, including:

- Z purlins - available in depths from 121mm to 265mm and a range of thicknesses. As a roof purlin supplier, we can supply zed section roof purlins drilled or un-drilled.

- C Section purlins – these are usually used to form walls and floor joists of a building. Again, they are available in a wide range of sizes.

What are steel purlins used for?

Steel purlins are an incredibly popular building material commonly used in the construction of industrial, commercial and agricultural buildings. They are designed to support the weight of the roof and deck and run parallel to the building’s eaves beam.

Different types of roof purlins exist. They are divided into types based on the material from which they are made and their shape.

Roof purlins are crucial to the integrity of a roof because without them there’s no frame for the metal sheeting on the roof to rest on.

How do you select the right size roof purlins?

Roof purlins are available in a wide variety of sizes and can be installed in several different ways. In the industry, the installation method is referred to as ‘run systems’. The specified run system dictates how far your roof purlins need to reach.

As a leading roof purlin supplier these are the most common run systems, we supply roof purlins for:

- Continuous lapped – where two steel purlins overlap in the centre for added support

- Single span – a single purlin covers the length of the structure

- Double roof purlin span – where two roof purlins are supported at the ends and centre

- Double lapped – where steel purlins are supported at each end by a series of overlapping purlins

Once you are aware of the run system you need, you must work out how many roof purlins you require. You will need to know how far away from each other the roof purlins need to be (usually no further than 1.2m apart when using metal sheeting with a thickness of 0.7mm, an 1m if using 0.5mm). You can then work out the size you need.

As one of the leading roof purlin suppliers in the UK, there’s nothing we do not know about steel purlins, including Z purlins, C purlins for sale, and eaves beams. Simply give us a call if you have any specification questions.

What is the structural difference between Z purlins and C purlins?

Builders tend to use C and Z purlins within steel framed buildings to provide a structurally sound, lightweight, cost-effective roofing, cladding and walling system.

However, other than the shape of C and Z purlins, what are the main differences when it comes to specification?

The main difference is that Z purlins are much stronger than C steel purlins due to their continuous overlapping capability. Therefore, Z purlins are usually used as roof purlins whereas C purlins are used to form walls and floor joists.

There are some instances where C purlins may be chosen in roofing. However, here are a few things to consider when specifying steel purlins:

- If the metal building has continuous spans, Z purlins are better because they can be continuously overlapped, where C steel purlins cannot.

- Continuous overlapping with Z steel purlins also increases the roof loading capacity.

- With the moment of inertia on a Z purlin’s weak axis is far larger than a C purlin, therefore it works far better from a building integrity point of view.

- If a metal building is installed with concealed fixing or flip lock panels, Z roof purlins are better than C purlins

How far apart should purlins be on a metal roof?

As a typical guide, metal roof purlins should be at least 50mm wide to enable roof sheets to be easily fixed. Steel purlins should also be spaced no further than 1.2m apart (when using 0.7mm sheets) and 1m with 0.5mm sheeting. Of course, exact specifications will differ, but this is a good general guide to follow.

The most important thing to remember is that steel purlins must be correctly spaced and within specified tolerances, or the mass of the roofing sheets could damage them and make them ineffective.

As a leading roof purlins supplier, we have a vast range of Z roof purlins and C purlins for sale. Our Z purlins, for instance, are made from structural-grade galvanised steel and are available in depths of up to 265mm and lengths of 9m.

For further information, browse our blog, view our menu of categories, or check our terms to see how you can save on bulk orders of Steel Purlins and related products.