Prestige Industrial Roofing Supplies are the UK’s leading Rubber Roofing Supplier.

We deliver roof sealing paint, waterproof roof paint, liquid rubber roof coatings, EPDM roofing and rubber roofing supplies nationwide.

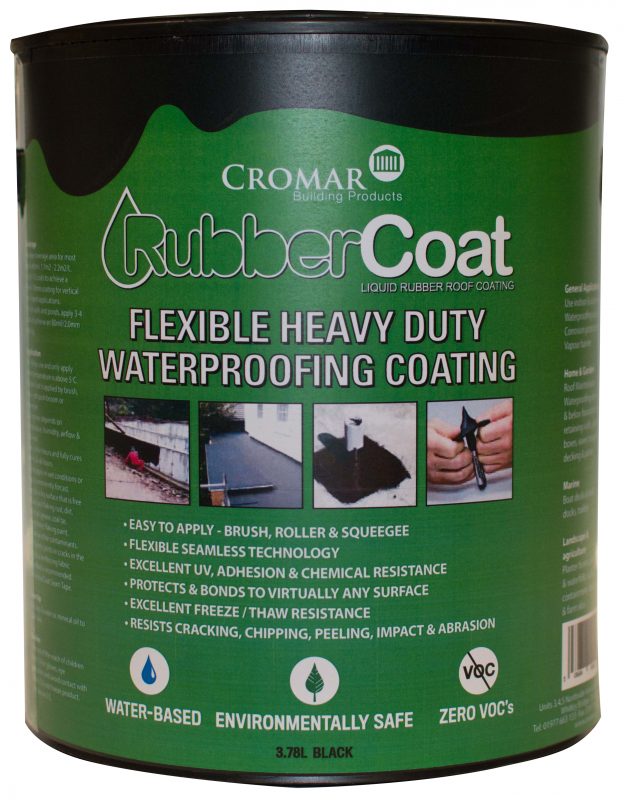

As a leading roof sealing paint products supplier, we offer a comprehensive and competitively priced range of waterproof coatings. These include acrylic roof coatings, polyurethane waterproof coatings (PU), glass reinforced polyester (GRP), EPDM membranes, liquid rubber roof coatings and Cromapol waterproofing roof paint.

If you’re looking for a quick, straightforward solution for a flat or pitched roof, we have a wide range of liquid and rubber roofing material and products to choose from.

We Stock Only the Best Rubber Roofing Material Manufacturers

We only work with and supply high-quality products from trusted manufacturers. These include Cromapol, Elastathane and Pro-GRP to name but a few. This means you can that you can have total confidence in the products we supply, many of which come with robust manufacturer warranties. We offer our customers the advantage of being able to obtain all the products, tools and equipment they require from a single, reputable source.

Close links with major steel roof decking manufacturers mean that we can provide quality products at competitive rates. We supply the best roof waterproofing supplies from manufacturers such as Cromar, Res-Tec, Flex-R and many more. As a result, you can purchase all your roof sealant paint and rubber roof membrane supplies from us.

Protecting flat and pitched roofs, corrugated asbestos, roof lights and flashing has never been easier.

Prestige stocks a variety of liquid rubber roof paint, liquid rubber latex and liquid waterproofing systems to suit all applications. Additionally, for a single GRP resin option, we’ve introduced Flexitec 2020 that provides full overlay and new deck capabilities.

So, if you’re looking for a roof waterproof coating supplier that offers a quick way to fix a leaking roof in one coat, we can help.

Best of all, we’ve made the purchasing process simple. Since we have many years’ experience in the trade, we co-ordinate your deliveries to help keep your project on track. Our national logistics network delivers the rubber roofing supplies you require quickly, easily and cost-effectively.

Rubber Roofing & Waterproof Coatings FAQs

What is rubber roofing?

Known in the building trade as EPDM roofing (ethylene propylene diene terpolymer) roof, rubber roofing is made from rubber or plastic polymers (sometimes a combination of both).

Rubber roofing can be used on either pitched or flat roofs, but it is more common on flat roofs that are prone to water pooling. EPDM roofing helps the water run off quicker and is less likely to crack in extreme weather conditions when compared to asphalt.

Similarly, rubber roofing material offers excellent thermal shock resistance and will not crack or go brittle with heat. Likewise, EPDM roofing is equally as resistant to UV radiation.

How long does rubber roofing last?

Rubber roofing, also referred to as EPDM roofing, is exceptionally hard wearing and can easily last 30-50 years although manufacturer warranties tend to be around 25 years.

Rubber roofing requires very little maintenance as well. If installed correctly, in line with the manufacturer’s instructions, it is very unlikely to crack or leak. However, if you do experience any cracks outside of the warranty period, there is a wide range of rubber roofing sealants that can resolve the problem.

How is rubber roofing installed?

Rubber roofing is often far quicker to install than asphalt or slate roofing materials. The most efficient way to install EPDM roofing is in a seamless roll. With no seams, it is less likely to crack as there is nowhere for water to seep into.

Obviously, if you are installing rubber roofing shingles, these will need to be secured much like traditional shingles. However, if you are laying an EPDM roofing roll, you will need to trim it to the shape of your roof, making sure you allow for chimneys, rooflights etc…

Before laying the rubber roofing, you must clear the space beneath of dirt and debris and apply the correct adhesive before laying.

Of course, there is another option and that’s a liquid rubber roof. Liquid EPDM roofing can be applied by hand or sprayed on. The usual way to apply liquid rubber roofing though is to pour the liquid in a line over the area, and then spread it evenly with a specialist roller.

How long does rubber roofing last?

You can expect EPDM rubber roofing to last between 30 to 50 years. If installed properly the rubber roof membrane will protect a building even in the harshest of weather conditions. EPDM roofs that have passed UL tests are considerably tough, insulate properties efficiently, reflect UV rays, and withstand weather effects efficiently. Rubber roofing material is even durable enough to support rooftop gardens since it is incredibly good at locking moisture and preventing any bacterial or fungal growth.

Seamless sheets of rubber roof membrane require a good installation to make sure they perform as expected though. Therefore, you will need to choose the contractors who are proficiently trained in rubber roofing installation.